Cold Room Panels

Cold room panels are key components used to construct the walls, ceilings, and other structures of cold storage facilities. Their main functions are to provide thermal insulation, maintain a low-temperature environment, and provide structural support.

Send Your Inquiry Today

Cold Room Panels Manufacturer in China

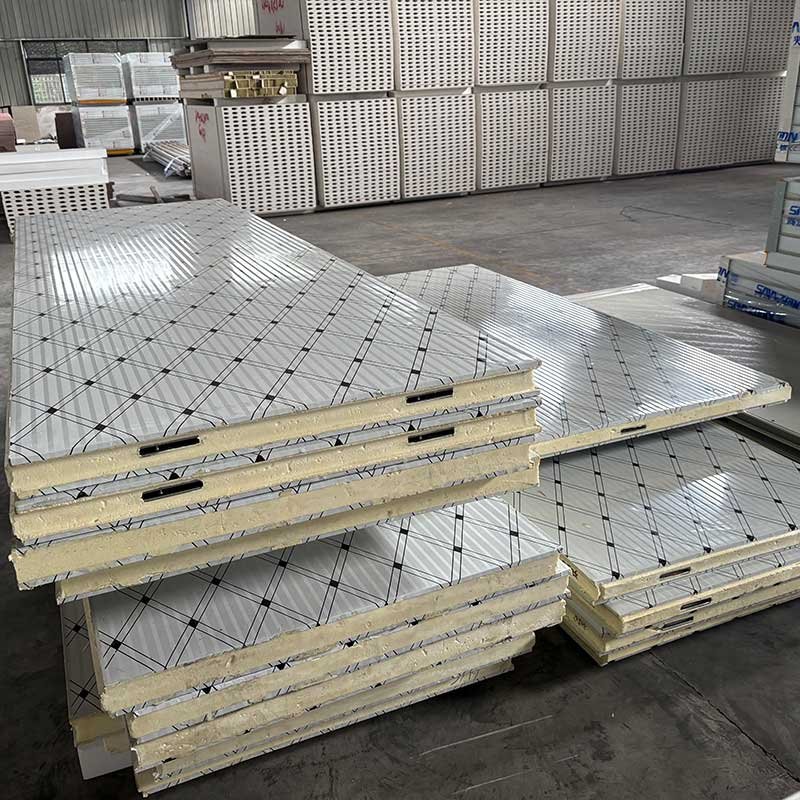

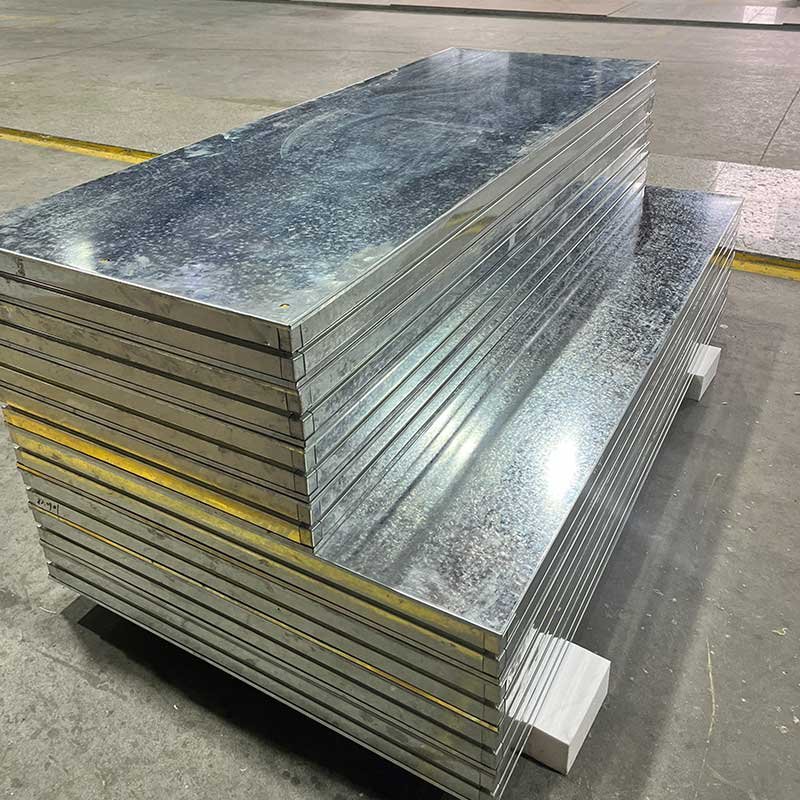

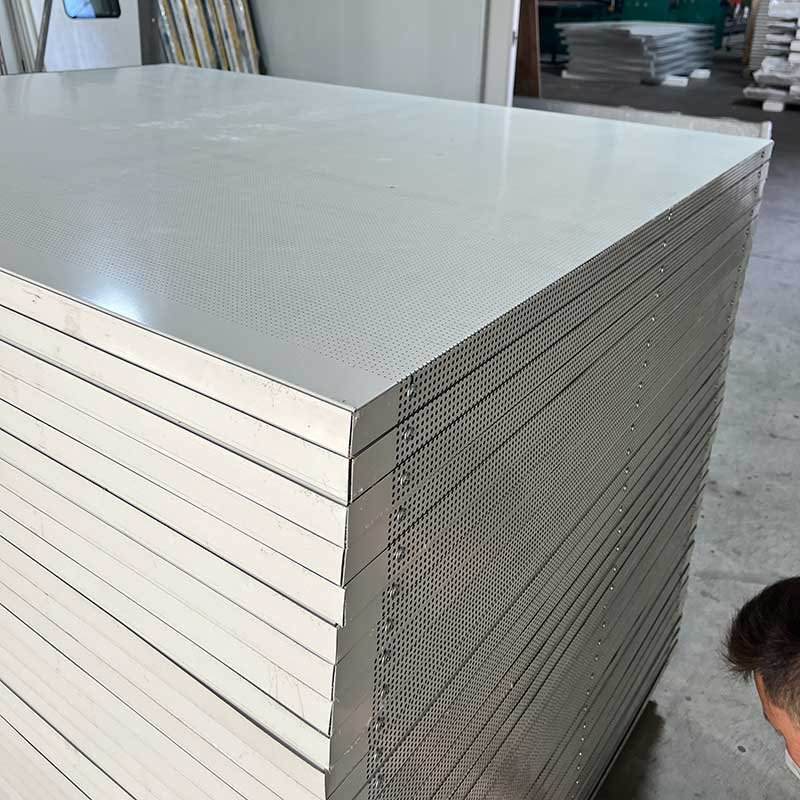

Cold Room Panels are typically sandwich structures, consisting of metal or composite material panels on both sides and an insulating core in the middle. The panels are generally made of galvanized steel, color-coated steel, or stainless steel, offering good strength and corrosion resistance. Depending on the core material, cold storage partitions can be categorized into several types: PU, EPS, rock wool, and PIR.

Our cold room panels are designed for different goods with varying temperature requirements (e.g., meat requires -18℃, fruits and vegetables require 0-4℃). These partitions divide the cold storage into multiple temperature zones, allowing for individual temperature control. The partitions effectively reduce the disorderly flow of cold air within the storage area, preventing cold energy waste and reducing compressor operating frequency, thus saving energy. The partitioned design facilitates categorized storage, labeling management, and rapid retrieval of goods, making it particularly suitable for large logistics cold storage facilities or multi-functional cold storage units.

Different Material of Cold Room Panels

Using Our Cold Room Panels Can Save Labor and Construction Time

Send Your Inquiry Today

Advantages of Using Cold Room Panels

Send Your Inquiry Today

Cold Room Panels Connection Method

Send Your Inquiry Today

Explore More Via Video

Customization Options

SamZoon offers flexible customization solutions to meet diverse production needs. From core materials and panels to performance parameters and branding elements, each sandwich panel is optimized to improve production efficiency, achieve smooth operation, and create a unique brand image.

Send Your Inquiry Today

Why Choose SamZoon Cold Room Panels?

Real-World Sandwich Panel Solutions

Learn how businesses across industries are using SamZoon cold room panels solutions to overcome fire safety hazards. From excellent thermal insulation to strong fire resistance and superior sound insulation, our sandwich panels help businesses save energy, reduce consumption, and lower operating costs.

Send Your Inquiry Today

SamZoon

The First Choice for Global Customers

Send Your Inquiry Today

About Our Factory

FAQS

What Our Customers Say about Fiber Sandwich Panels

Indonesia

Eps Sandwich Panel

UAE

Eps Sandwich Panel

Uganda

Eps Sandwich Panel